Integrated Wafer Handling Systems

EFEM Systems

Integrated Wafer Handling Systems

EFEM Systems

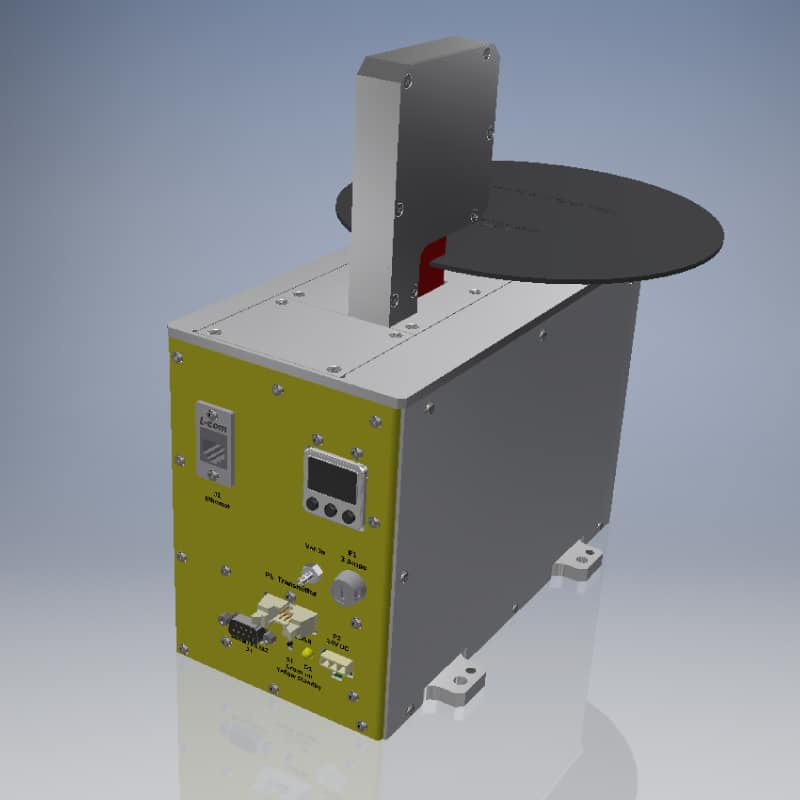

DLP-300 EFEM

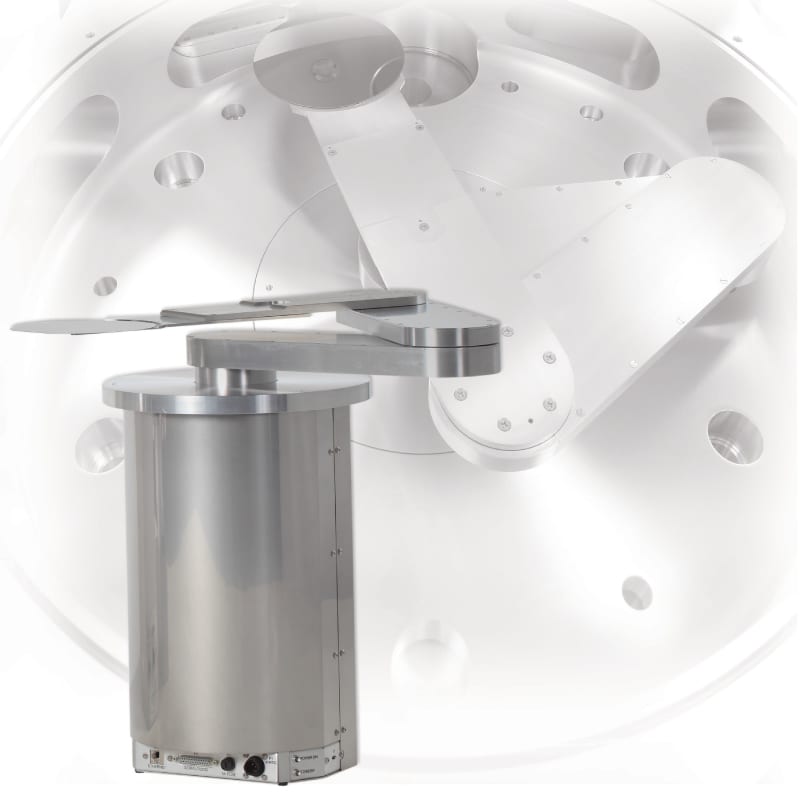

An Equipment Front End Module (EFEM), a mainstay of semiconductor automation, transports product (silicon wafers or quartz photomasks) between ultra-clean storage carriers and a variety of processing, measurement, and testing systems. The EFEM contains the key components needed to unload product, deliver it to the parent tool for processing and return the product to its carrier upon completion.

The DLP-300 EFEM is designed to be used with an existing OEM GEM base system and can be configured to handle a variety of wafers sizes from a maximum of 2 load ports to 2 load locks. In addition, Angled Transfer Chambers or process modules connect directly to the rear of the DLP-300.

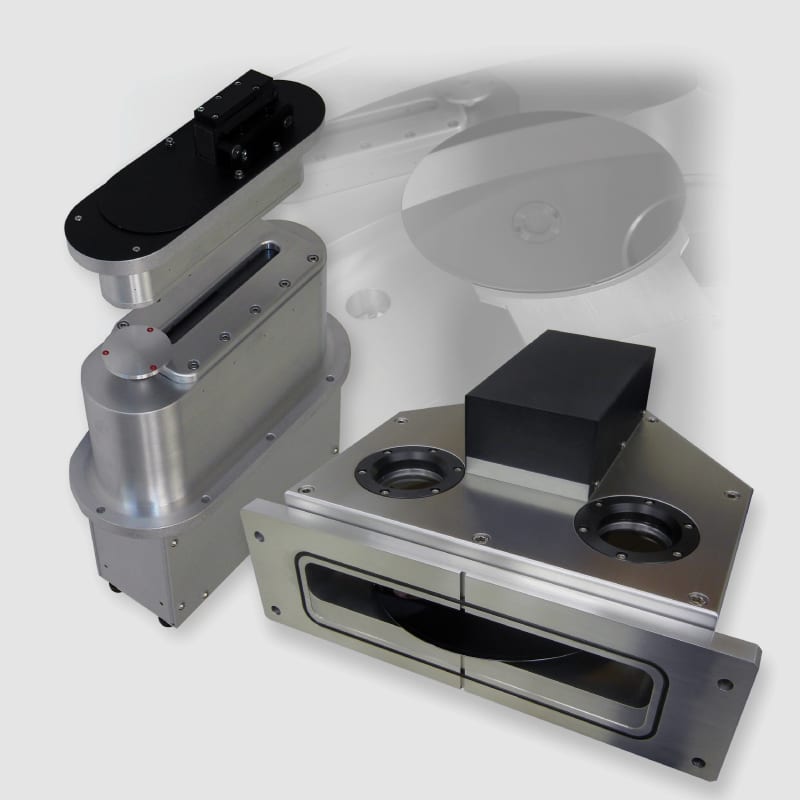

The DLP-300 hardware supports up to two load ports, an atmospheric robot with an end effector, a power system with safety circuits, a fan filter unit, a user interface, an aligner, a frame, and skins.

The base configuration accepts open cassette load ports for 150mm and 200mm wafers, SMIF load ports for 200mm wafers, and FOUPs for 300mm wafers. These load ports are designed to automatically detect the loaded transport wafer carrier size with its presence sensors or Infopad.

The system implements unit-level software that communicates with the components within the DLP-300 (robots, load ports, aligners, valves, fans, etc.) However, the OEM is responsible for integrating communication with their platform.

FEATURES

OPTIONS

PRODUCT SPECIFICATIONS

General | |

Operating/Storage Temps Wafer Sizes | Width: 1377 mm (54.2") 20˚C to 30˚C 100, 125, 150, 200, 300mm Standard SEMI M1 |

Throughput | |

Max Processing MCBF MTTR Wafer Breakage Rate MTTR | > 60 wafers per hour (no process delay with vacuum end effector) > 5 x 10^5 transfers < 2 Hours > 5x10^5 < 2 Hours |

Environment | |

Upon Request FFU ULPA Option FFU ULPA Option NO FFU Option | ISO Class 3 and Class 1 configuration options available. ISO Class 1 per ISO-14644-1 during wafer transfer and under static condition ULPA/PTFE Filter catches 99.99995% MPPS of particles 0.12 microns and above. PTFE Filter with integrated ionization & dual LED "Lumifilter" light bars is ISO Class 1 compatible. Mini-environment cleanliness is dependent upon installation environment cleanliness. |

Regulatory Compliance | |

SEMI S2 SEMI S2 |