Hine Outperforms Industry During Global Supply Chain Disruption

IT Administration

June 16, 2022

Hine Outperforms Industry During Global Supply Chain Disruption

Unprecedented supply chain disruptions have touched everyone across the globe, from automotive and medical industries to workers and consumers. Several factors have hampered supply chains over the last two years, including Covid-related production issues, labor supply challenges, the semiconductor shortage within the automotive industry, and the war in Ukraine.

Through this uncertainty, the semiconductor equipment industry is experiencing growth. According to SEMI World Fab Forecast, the industry is projected to increase its fab capacity through 2024: 200mm fab capacity is expected to grow by 20 percent, and 300mm fab capacity is expected to grow by 44 percent. However, it hinges on the production and installation of additional semiconductor manufacturing equipment (SME) and expanding SME production in these conditions comes down to ensuring an adequate and reliable supply of semiconductors.

Like many of its customers and suppliers, Hine Automation has experienced the impact including a shortage of parts and extended lead times. However, it has found ways to mitigate the supply chain disruptions successfully.

“Our industry specifically has seen quite a bit of disruption, including lead times for acquiring parts that take up to a year or more,” said Scott Craver, chief executive officer of Hine Automation. “Additionally, the delays touch different components, not just our products, but our competitors’ products, so we have had to be creative in sourcing materials.”

Better Lead Times with Preparation and Long-Term Relationships

Hine Automation addressed the diversity and continues to offer its customers standard lead times and, in some cases, the company exceeded delivery expectations. For example, in early 2022, from the time a purchase order was received from the customer, Hine Automation was able to expedite a full 6-sided vacuum handler configured with one CLP and elevator, optical aligner, robot, and end effector, all well within the standard lead time.

Outperforming the market and delivering vacuum and atmospheric robot components and handlers weeks or even months ahead of its competition has been a welcomed relief for Hine Automation’s customers, who can still meet their operational goals.

Craver added, “There’s always a need to challenge yourself in new ways. I can say we’ve got a great team who continuously looks for new and creative methods to manage the ongoing supply chain issues. Additionally, we can credit our success in mitigating the supply chain disruptions to our supplier partnerships, the relationships with our customers, and the investments we’ve made within our supply chain. It takes a good strategy and an all-in attitude to manage the demand and support our customers’ needs. I am grateful we have that here.”

About Hine Automation

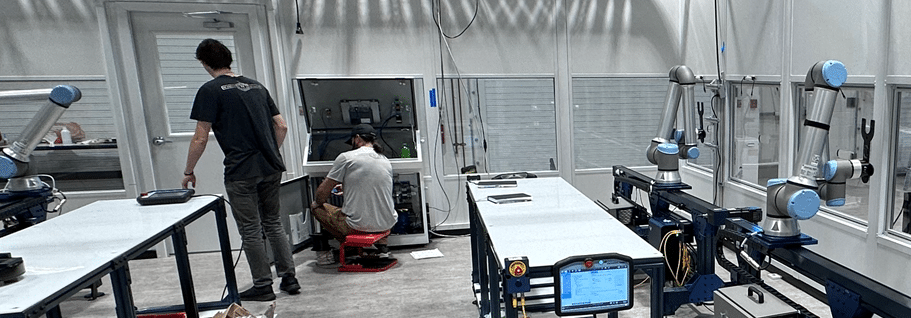

Hine Automation designs and manufactures vacuum and atmospheric automation systems and robotic components. Our team has been designing products for more than 30 years and serving our customers since 2009. For more information, visit us at HineAutomation.com