A Deep Dive into the Transformative Power of Wafer Fab Equipment

Hine Automation Team

December 28, 2023

From powering smartphones to driving medical devices, semiconductors play a pivotal role in a wide range of technologies. At the heart of this complex manufacturing process is wafer fab equipment, serving as the fundamental framework for semiconductor production. As technology advances, the semiconductor industry is undergoing a transformative shift marked by the introduction of a cutting-edge generation of wafer fab equipment.

As 2023 winds down, we’ll look ahead and discuss the transformative capabilities of the emerging tools, explore their enhanced performance, heightened accuracy, flexibility, and seamless integration into existing systems.

Unleashing a New Era of Semiconductor Manufacturing

The new generation of wafer fab equipment represents a leap forward in semiconductor manufacturing. This technology boasts unparalleled performance, precision, flexibility, and seamless integration capabilities, marking a significant turning point in the industry.

The Power of Speed and Precision

The relentless demand for faster and more efficient semiconductor production has spurred the development of wafer fab equipment with unparalleled performance capabilities. Increased speed and throughput address the industry’s persistent need for higher efficiency. Additionally, precision and accuracy improvements will further contribute to the equipment’s efficacy, ensuring the production of semiconductor components with minimal defects.

Adapting to the Evolving Landscape

Adaptability is a crucial determinant of success. The new generation wafer fab equipment shines in its ability to cater to various semiconductor processes, offering a level of customization that was previously unprecedented. This flexibility accommodates diverse applications and positions manufacturers to respond swiftly to evolving market demands.

Seamless Connectivity for a Unified Manufacturing Ecosystem

Seamless integration into existing systems has long been a challenge for manufacturers upgrading their equipment. The new generation wafer fab equipment addresses this hurdle, boasting compatibility with industry standards and a user-friendly interface. This not only streamlines the transition process for manufacturers but also ensures a cohesive and interconnected manufacturing ecosystem.

Leveraging Innovative Technologies for Unprecedented Advancements

The transformative power of the new generation of wafer fab equipment includes advanced sensors, artificial intelligence, machine learning, the Internet of Things (IoT), and advanced packaging. These technologies are not just buzzwords but tangible components that contribute to higher accuracy, improved efficiency, and cost savings for manufacturers.

- Advanced Sensors: These forward-looking sensors offer increased levels of precision, enabling real-time monitoring and control. The impact on accuracy and quality control contributes to the enhancement of the semiconductor manufacturing processes.

- Artificial Intelligence and Machine Learning: The new wafer fab equipment leverages AI and ML algorithms to optimize processes, learn from data, and adapt to changing manufacturing requirements. This not only improves the efficiency of the equipment but also positions manufacturers on the frontier of smart manufacturing.

- The Internet of Things: IoT connectivity plays a pivotal role in enabling seamless communication between various manufacturing process components. This connectivity facilitates real-time decision-making, predictive maintenance, and a holistic view of the manufacturing landscape.

- Advanced Packaging: Advanced packaging technologies involve integrating multiple semiconductor components, such as chips, memory, and sensors, into a single package to improve performance, power efficiency, and form factor. These technologies are critical for developing compact, high-performance electronic devices, such as smartphones, tablets, and wearable devices.

Harnessing the Benefits of New Technology

The transformative capabilities of the new generation of wafer fab equipment translate into tangible benefits for semiconductor manufacturers.

Improved Yield and Quality

One of the primary concerns in semiconductor manufacturing is the yield and quality of the final products. The new generation wafer fab equipment addresses this by significantly reducing defect rates. The advanced sensors and AI-driven quality control mechanisms contribute to a more refined manufacturing process, ensuring a higher yield of top-quality semiconductor components.

Increased Efficiency and Cost Savings

Enhanced performance and flexibility directly translate into increased efficiency and cost savings for semiconductor manufacturers. Higher throughput rates, coupled with a reduction in operational costs, enable manufacturers to operate more competitively. The streamlined manufacturing processes contribute to overall operational efficiency, ensuring a balance between quality and cost-effectiveness.

Accelerated Time-to-Market

Streamlined processes, rapid prototyping, and development capabilities empower manufacturers to quickly bring new semiconductor products to market. This caters to the demands of the fast-paced tech industry and provides a competitive edge to manufacturers.

As the industry embraces these changes, a future where semiconductor manufacturing is both efficient and highly intelligent and interconnected is within reach.

Final Thoughts

The trajectory of wafer fab equipment points toward the continual exploration of technological frontiers. According to market research analyst, Technavio, the wafer fab equipment market is anticipated to grow substantially, projecting an increase of USD 43.94 billion from 2022 to 2027. Analysts foresee a surge in demand for these cutting-edge tools as manufacturers increasingly realize the imperative to stay competitive in the swiftly changing technological landscape.

Companies that embrace these innovations position themselves as industry leaders and architects of the technological future. It is evident that the new generation of wafer fab equipment is not just a tool but a catalyst for progress, propelling the semiconductor industry into a future of endless possibilities.

Why Choose Hine Automation?

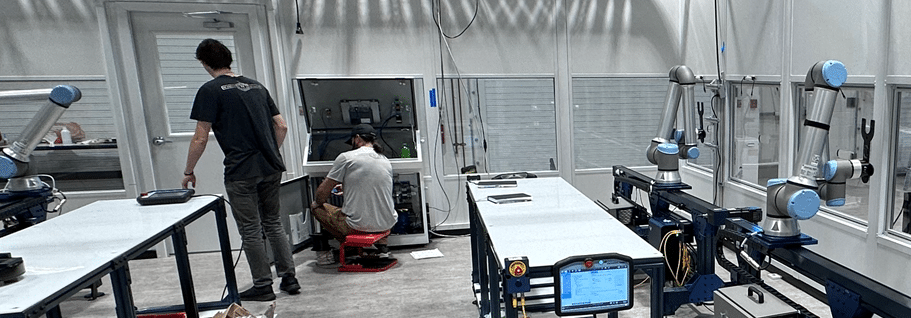

Hine Automation’s state-of-the-art wafer handling systems are meticulously designed to elevate your production capabilities, offering unparalleled performance, precision, and seamless integration.

Hine leads the charge in quality, performance, and customer support:

- Innovative Technology

- Tailored Solutions

- Streamlined Integration

- Efficiency Redefined

Contact Hine Automation today to explore how our cutting-edge wafer handling systems can propel your company into a realm of endless possibilities.