Collaboratively Designed Custom Solutions to Address Unique Specifications

Hine Automation Team

March 24, 2020

Collaboratively Designed Custom Solutions to Address Unique Specifications

Case Study,Latest Articles

March 24, 2020

SSometimes handling and transporting certain substrates is not straightforward. This is because everything in this world requiring handling is not a specific standard size. While Hine Automation is extremely capable of meeting the handling requirements of standard sizes, our adaptability also allows us to handle non-standard sizes with ease. In this case study, we highlight the versatility of the Constellation, our cassette-to-cassette transport system, as a process chamber automation solution.

The Customer Faces an Automation Challenge

Our customer needed to automate their process module using a cassette-to-cassette transfer system. The unique challenges that our customer faced were:

Cost Effective Platform: The customer required a 300mm platform with atmospheric load ports for a very cost sensitive application.

Non-Cleanroom Environment: This application was performed in a non-cleanroom environment with unique wafer cassettes.

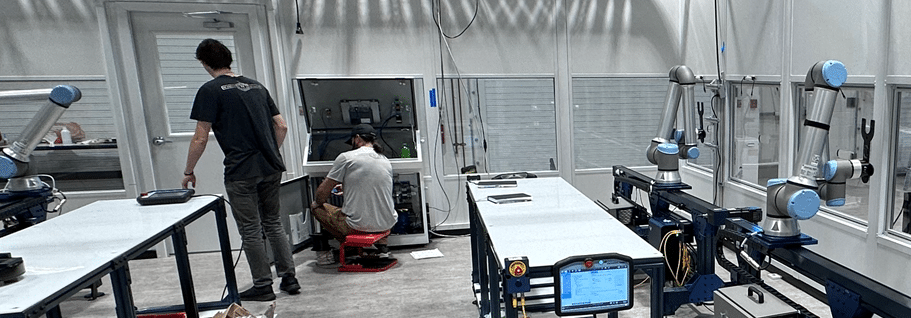

Hine Automation develops a Custom Solution

Our challenge was to create a reliable product capable of operating in an atmospheric environment, handling unique size substrates with unique cassettes, while at the same time meeting budget constraints. Hine’s engineering team met this challenge by using our 2-axis robot instead of our 3-axis robot as the central handler for the system. The Constellation HA-4300, our cassette-to-cassette transport system, was the perfect candidate for this job. This front-end solution for 300mm perfectly met the customer’s needs. Additionally, Hine designed an atmospheric front-end that accommodated the unique wafer cassettes used in this application, thus dramatically reducing the overall cost of the system.