Extending the Lifespan of Hine Automation’s 12-Inch Robotic Arms with Nickel Plating

IT Administration

March 27, 2023

Extending the Lifespan of Hine Automation’s 12-Inch Robotic Arms with Nickel Plating

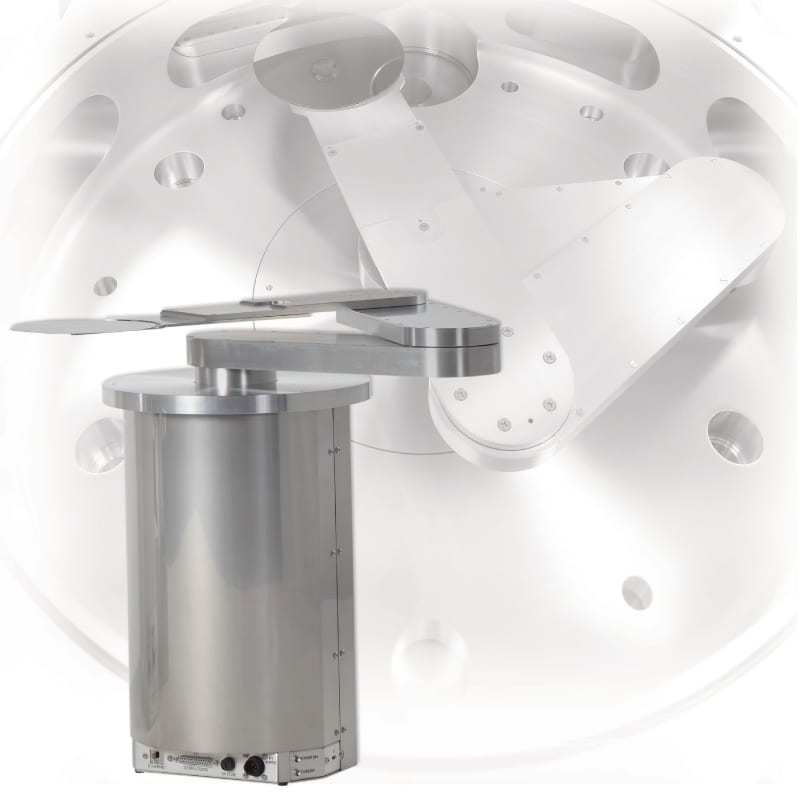

Designed as the central handling robot for Hine Automation’s Constellation Systems, our vacuum robotic arms can be integrated with all vacuum wafer handling systems we manufacture. Our goal is to design and build the most cost-effective solutions for our customers, so we have introduced the option to nickel plate our 12-inch robotic arms.

Robotic arms transfer wafers in and out of the process chamber with extreme precision. This accuracy requirement dictates the need for tight tolerance adherence for the components used in assembling the robot. Additionally, the robotic arm is one of the main assemblies that can be exposed to various harmful gasses.

The Durability of Your Investment

One of the many steps of manufacturing Integrated Circuits (ICs) is Plasma Processing, performed in a vacuum process chamber. Initially, the robot sits in the transfer module, takes the wafer, and places it into the process chamber. The robot then exits the process chamber and the slot valve closes, which allows the customer to reduce the process module pressure for processing. Once the slot valve reopens, some residual gas may escape into the transfer module.

Some of these residual gasses are corrosive, which can adversely affect components inside the chamber. Nickel plating is known for improving the appearance of an object, but its true benefit in manufacturing is the ability to provide a barrier that resists corrosion, wear, and tear. Nickel is less reactive and protects by sealing the surface from the atmosphere. Nickel plating of the exposed robotic arm extends the life of these parts due to corrosion resistance properties.

Design Customization is Required

To ensure precise wafer handling, nickel plated components must be customized to the actual dimension of each part. For example, when you nickel-plate a robotic part, it dimensionally changes every other part during assembly. An extensive redesign is needed to address the modification and ensure every part fits perfectly and moves smoothly. Therefore, the nickel-plated components along with other components that may be affected due to tolerance stack up all need to be dimensionally updated. Upon completion, all affected parts are manufactured to tight tolerance specifications.

Final Thoughts

Many different gasses are used in processing semiconductor wafers and making ICs. Some are more corrosive than others. Therefore, extending the lifespan of your robotic arm with nickel plating is an important consideration for your business. Not only will nickel plating prolong the life of your investment, it’s also a cost-effective solution that maximizes production and minimizes downtime.

About Hine Automation:

With more than 30 years of deep experience in the semiconductor space, Hine’s technology and design development are consistently relevant to the evolving market. Whether in the very early stages of a project or modifying an existing solution, Hine sets the precedence of uncompromised quality and versatility in design and manufacturing.

For more information on Hine Automation, visit our website: https://hineautomation.com/.