Hine Automation Leverages Custom Engineering to Exceed Customer Expectations

Hine Automation Team

December 13, 2022

Hine Automation Leverages Custom Engineering to Exceed Customer Expectations

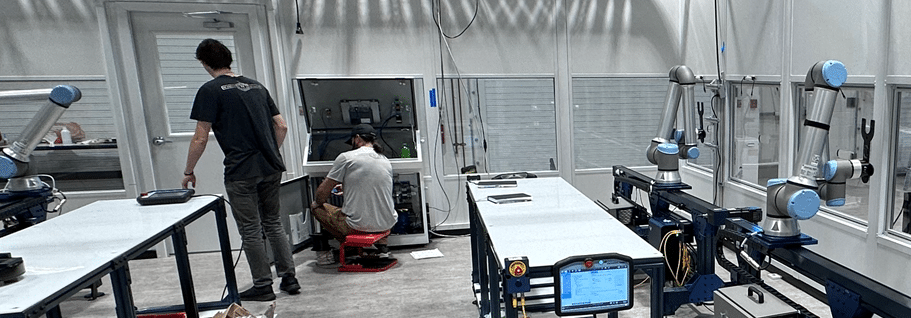

Hine Automation is passionate about turning product ideas into marketable solutions. Its ability to simplify the design and manufacturing process has led to a reputation known for quality and versatility. It is why customers continue to choose Hine over other manufacturers of robotic components and automation systems.

CHALLENGE

Long-term Customer Needed Customized Solutions to Streamline Processes

A leading OEM manufacturer of semiconductor process equipment developed a new product that called for a wafer cassette loader to interface with their platform. The design required custom engineering to deliver the desired specifications. However, the right solution only comes when both teams work well together with complete transparency.

Hine’s engineering team has a solid history of working with the longstanding customer to understand their specific goals and design needs. In this case, Hine was asked to create a new wafer cassette loader that would allow for multiple levels of functionality and integration to meet necessary technical requirements. Specifically, the OEM needed to seamlessly transfer four 150mm cassettes on a single tray into a process module to manage, in a single batch, 100 wafers or four cassettes.

SOLUTION

Customization in a Compact Design

Working with the customer to understand their unique challenges was critical to developing a solution that could quickly optimize performance and increase efficiencies.

Hine SL-4150

The SL-4150 is a custom vacuum load lock solution specifically designed for the customer to allow the transfer of four cassettes lying on their side into a process module/heating element. The SL-4150 uses dual two-way telescoping rails that enable a universal tray to reach into the customer’s process module under vacuum and reach beyond the door facet for the loading and unloading of the cassettes at atmosphere. The telescoping drive rail provides the ability to obtain standard reach requirements in a compact design.

The openings, over 17.5 inches on both the loading door and process module side, allow the use of larger substrates or carriers than what would traditionally be acceptable in standard load locks.

The SL-4150 offers features such as:

- A removable lid with safety switch and bezel allowing for the easy integration of a turbo or heater using an ISO200 port

- The ability to carry loads up to 20kg including transfer tray

- A Z-Lift option using RS-232 for communication

- A pneumatic safety rated door lock designed to communicate with interlocks

- Safety-rated heat sensors designed to communicate with interlocks

- Three KF25 ports strategically placed for Wafer Presence Sensors and for venting of the main chamber

- One KF40 port for pumping of main chamber

- 150mm Side view ports on both sides

- A free-standing welded frame

SUCCESS

Increased Product Performance with Streamlined Processes

Employing existing components to limit the amount of engineering time, Hine designed a cost-effective, customized solution. Custom engineering enabled the customer to implement an automated solution that directly addressed the company’s goals and helped them to take a new product to market.

Customer-first Approach Benefits

- Plug-and-play solutions

- Superior user experience

- Flexible and nimble

- Rooted in integrity and transparency

- Cost reduction

- Quality control

- Combined efficiency in speed and quality

FINAL THOUGHTS

Customer Insight, Flexibility, and Collaboration

With 30-plus years of deep experience in the semiconductor space, Hine’s technology and design development are consistently relevant to the evolving market. Whether in the very early stages of a customer’s project or modifying an existing solution, Hine sets the precedence of uncompromised quality and versatility in design and manufacturing.

For more information on Hine Automation, visit our website: https://hineautomation.com/.