Hine Engineers Customized Solution to Handle Material and Carriers with Precision on One Platform

Hine Automation Team

March 8, 2022

Hine Engineers Customized Solution to Handle Material and Carriers with Precision on One Platform

CHALLENGE

Increase Throughput, Opening up New Markets with Automation

Hine Automation sets the precedence for quality and versatility in design and manufacturing. Unlike off-the-shelf solutions providers, Hine is often challenged to create purpose-driven solutions to optimize performance and increase efficiencies.

A semiconductor equipment manufacturer approached Hine to develop an atmospheric solution with minimal engineering integration and software investment. They required a “sandwich-like” assembly whereby during the process of moving the material, the wafer is placed in between a carrier and a cover prior to being transferred into the Customer Process Module. Positioning of the wafer and rotational accuracy was critical.

To meet the needs of the essential components of the system, the global company required rotational alignment and positional accuracy correction of wafer, carrier and cover placement. This approach challenged Hine to build a customized End Effector design to handle the different materials of the assembly on one platform.

SOLUTION

Customization and Collaboration Expands Customer’s Offerings with Atmospheric Solution

The right solution comes when both teams collaborate and work together with complete transparency. Hine’s engineering experience, ability to listen to the customer’s needs, and then apply realistic design goals were all critical factors in the success of this project.

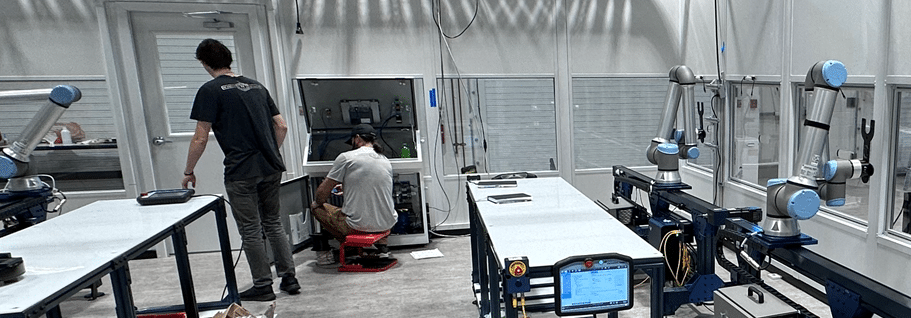

There was no longer a need for a vacuum chamber. However, the customer still required the system to utilize safety interlocks and clear panels to allow viewing of the internal components and movements. Leveraging existing core components from its HA-400 cassette-to-cassette vacuum transfer system, Hine designed the atmospheric system with the same robotics.

Following in the footsteps of Hine Automation’s Constellation platform, the HAtm-400 system is a four-sided cluster system that features one cassette load part and three additional facets. The proven reliability of the core components ensured high system uptime and reduced costs. In addition, utilizing the existing HA-400 vacuum system controls architecture, safety interlocks and sophisticated automation features such as wafer mapping and wafer cross-slot detection accelerates system integration.

The versatile design of the HAtm-400 became a cost-effective solution. Taking advantage of the same Hine controls architecture allowed the customer to use their existing software. However, by eliminating the need for the vacuum system, Hine could meet the customer’s requirements with a more cost-effective solution without compromising quality.

Features

- Hine Robotics: HA-5.0 Robotic Arm, ALP-200 Atmospheric Load Port, HA-175 Atmospheric Aligner

- High reliability of > 10 million MCBF

- Handles wafer sizes up to 200mm

- Sophisticated automation features including wafer mapping, wafer cross-slot detection

- Safety interlocks

- CE/SEMI S2 compliant

- RS-232 / Ethernet

SUCCESS

Custom Engineering is a Key Differentiator

The advantages of working with the right custom engineering team come down to the ability to streamline processes and increase product performance and value.

With the use of existing components to limit the amount of engineering integration time and the selection of an atmospheric pressure design, Hine Automation was able to design a cost-effective, customized solution for the customer.

Hine’s custom engineering enabled the customer to move to an automated solution that would directly address its goals and take a new product to market. The result helped to improve competition against more prominent players in its industry.

Customer-Focused Approach; Meaningful Results

- Collaboration leads to better design

- Improved user experience

- Better resource management

- Improved time to market

- Cost reduction

- Quality control

In the semiconductor industry, customer insight, flexibility, and collaboration are essential factors in the success of the custom engineering process. Whether you are in the early conceptual phase of your project; or have an existing solution that needs to be modified, Hine is a committed partner in the successful design and development of your customized solution allowing your team to focus on its core competencies.

For more information on Vacuum and Atmospheric Cassette Load Ports, visit our website: https://hineautomation.com/.