How Thin Film Technology Enables Innovation

IT Administration

May 9, 2022

Thin film deposition, or vacuum coating, can be likened to the suit of armor worn by a knight. The armor provides an extra layer, protecting the knight during battle or during daily operations, and even improving overall performance. Thin film vacuum coatings apply to a wide variety of applications specifically to add protection to anything from medical devices and compound semiconductors to consumer electronics and bathroom fittings.

The semiconductor industry relies heavily on each company’s ability to innovate and create quality thin films. Semiconductor device fabrication begins with the deposition of thin films of material on silicon wafers. Film is deposited as deliberately as one atomic layer at a time using a process called atomic layer deposition. However, chemical, or physical vapor deposition can be applied for faster, though less precise, application.

As devices get smaller with modern technology, defects as small as a single atom can significantly impact overall performance. As a result, both accurate measurements and carefully controlled manufacturing conditions play an equal part in the manufacture and application of thin films.

One Link in the Chain

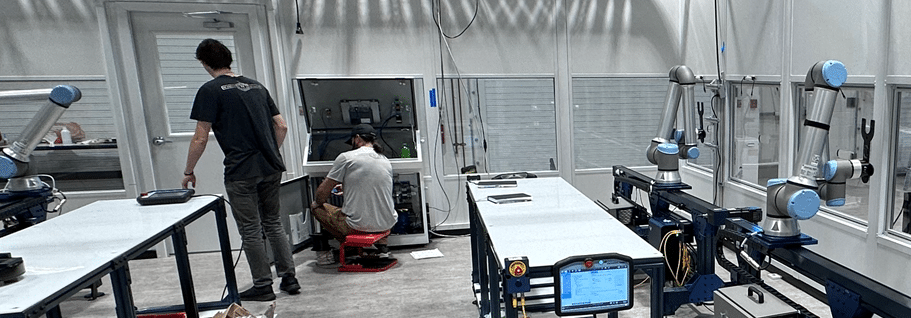

Thin film applications have always been an important topic for the semiconductor automation industry. As a single step in a long process, innovative robotic devices work to integrate thin film application into a complicated fabrication flow. These devices, each with their own benefits, help achieve desired film specs, monitor the deposition process, or increase automation and efficiency.

As many of today’s companies move towards providing more value beyond just finances and growing the business, they are also taking a hard look at how they and their employees can affect change and impact the lives of those around them. Incorporating thin film technology into their business models has opened up the world to new and creative advancements that influence our daily lives.

See the examples below of how thin films impact mega trends in healthcare, energy, and data storage.

Mega Trends and Unique Applications

Medical—A French start-up achieved a brain-on-a-chip technology and lens-less imaging approach that detects activity of neurons in brain tissue. The company states that faster processing power supports novel treatments for conditions such as Parkinson’s and Alzheimer’s. More information about this innovative chip and the company’s research can be found here.

Energy—Thin film applications in energy have led to advancements in solar paneling. Thin film lithium batteries continue to provide crucial energy when the sun goes down or the wind stops blowing. Read more on thin film solar paneling here.

Data Storage—In a sea of information, data storage continues to be a critical aspect of our daily lives, shaping simple activities such as sharing photos, saving financial information, or watching movies on demand.

What makes all this work?

Storage drives and solid-state memory, which rely on highly engineered thin films with specific read/write properties, store data and provide nearly instant retrieval.

For more information on how thin film is used to improve data storage, click here.

Consumer—Do you ever wonder how Rolex watches have such vibrant colors? Highly advanced thin film is used in their applications to bring a richer finish to the end product. Details on how the company has created such visual depth can be found here.

Thin Film affects us all

Thin film deposition has become an essential part of life. Finding any advanced activity without its presence is truly a challenge. The options are truly endless. However, no one-size-fits-all or perfect method exists when utilizing film; the application’s performance and production requirements ultimately determine the method of choice.

For more information on Hine Automation and its ability to integrate with any thin film OEM products, contact sales@hineautomation.com.