Testing and Preventative Maintenance Critical to the Longevity of a Robot’s Lifecycle

Hine Automation Team

May 4, 2023

Robots continue to increase production by performing a variety of tasks across the manufacturing industry. Additionally, manufacturers need to depend on these robots to operate at the highest levels of efficiency. So, when there’s even more pressure to minimize downtime, we need to go beyond and continue to innovate to ensure reliability and durability.

The pursuit of performing at the highest levels is all about testing and predictability—no surprises, no bottlenecks, and no unplanned downtime. A willingness to push innovation and improve state-of-the-art robotic components and automation systems ensure a robust solution.

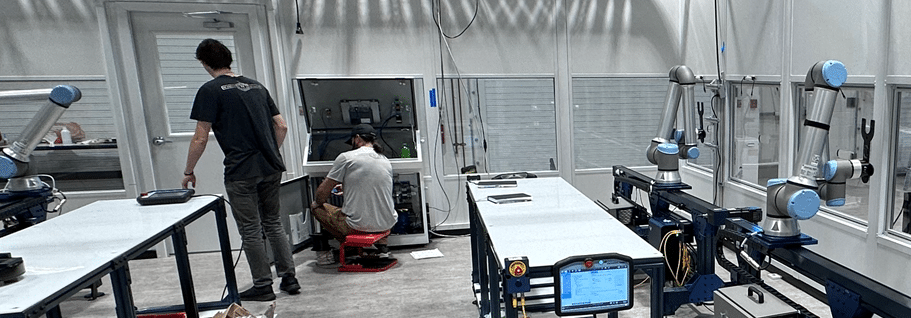

Repetitive Testing to Collect Critical Information

A robot failure can force unplanned downtime and the loss of production. It could take days to weeks to source parts and schedule the necessary repairs. As a result, companies can expect thousands of dollars to be lost in production costs.

When we look ahead to determine where the weaknesses may be due to wear and tear, maintenance schedules can be adjusted to perform repairs before the need presents itself.

To learn when these maintenance milestones occur, we must conduct repetitive testing and test to failure. This accelerated lifecycle testing is needed to exercise the robot at a much higher rate than would typically be used, and you do it continuously, 24 hours a day, seven days a week.

Calculating the average time between failure and reliability using theoretical values is common, but actually running a test to see what’s possible, pushing the limits to what the robot can withstand with greater accuracy of information, shows commitment to quality and reliability. For example, we can heat certain components to increase the wear in order to identify the failure points. We can target those markers, analyze the failure and make changes to mitigate the problem.

The only way to get examples of failure is to run tests. However, the sum of those tests is not weeks or months, but sometimes years.

The Significance of Preventative Maintenance

The most significant issues come from unscheduled downtime. The ability to control what needs to be maintained and schedule the timing accordingly ensures operational deadlines are met.

It only takes one component to shut down production, and the disruption could damage the ability to meet your customer’s needs. However, the issue might not be about an actual failure. For example, components can stretch over time causing the robot to become less accurate. Scheduled maintenance could address this issue and make adjustments to the robot to increase its lifecycle.

Benefits of Proper Maintenance:

- Detect and diagnose any concerns that may turn into problems.

- Provide analytics and alerts operators to make adjustments if needed.

- Reduce maintenance costs.

- Increase machine performance.

- Increase equipment lifespan.

- Utilize resources more effectively.

- Fewer equipment failures.

When you put reliable data in the hands of the customer, you are arming them with the ability to determine when they can schedule routine maintenance within their project timelines. Whether it’s an end effector or other critical components, maintenance can be arranged simultaneously, saving valuable resources and reducing overall operational costs.

Reliability and Uptime, Critical Areas of Focus

Ensuring the highest level of functionality in the most extreme conditions is how you put customers first. When you are reliable, you keep good data to make the decisions that will prevent the shutdown of production. To do that, you need a solid maintenance schedule to eliminate any failures.

When you plan maintenance, you can prepare people and the necessary parts. Then, when a robot lands on our dock scheduled for routine maintenance, we will make the necessary adjustments quickly. However, if your system fails because you didn’t do the required maintenance, engineering resources might be tight, or a part might not be readily available, costing you times and resources.

The constant pursuit of excellence and superior service is why Hine pushes the limits on what’s possible every day. We are always looking at innovative ways to offer our customers a solution that not only helps to drive operational costs down, but also exceeds higher performance.

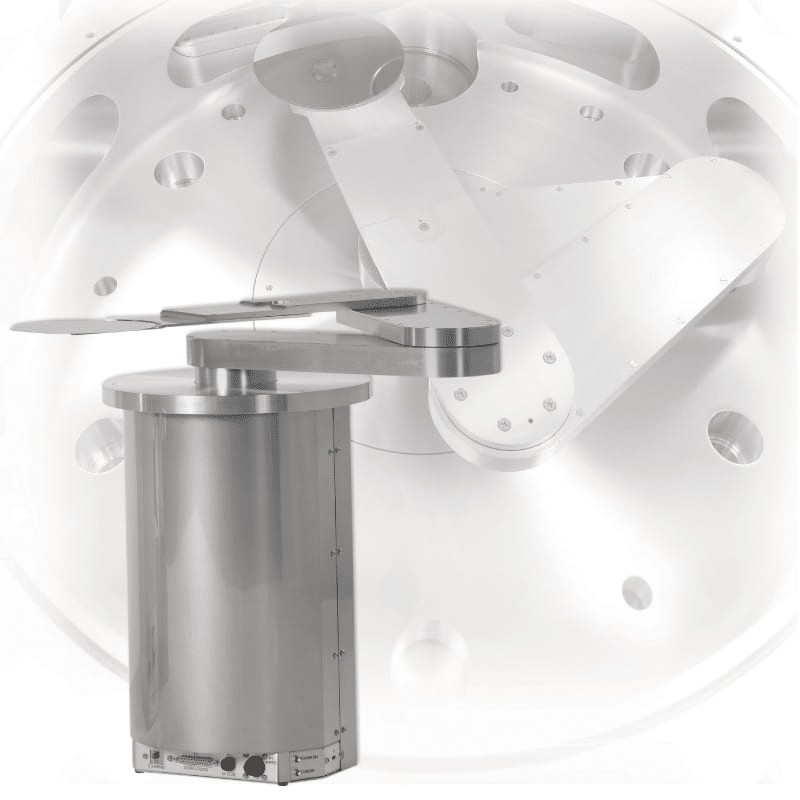

About Hine Automation

With more than 30 years of experience designing and manufacturing vacuum, atmospheric automation systems and robot components, we understand the importance of testing and preventative maintenance to keep your systems running as efficiently as possible. Contact us today or visit us at HineAutomation.com to learn more.