Vacuum Cassette Load Ports

Vacuum Cassette Load Ports

Vacuum Cassette Load Ports

Vacuum Cassette Load Ports

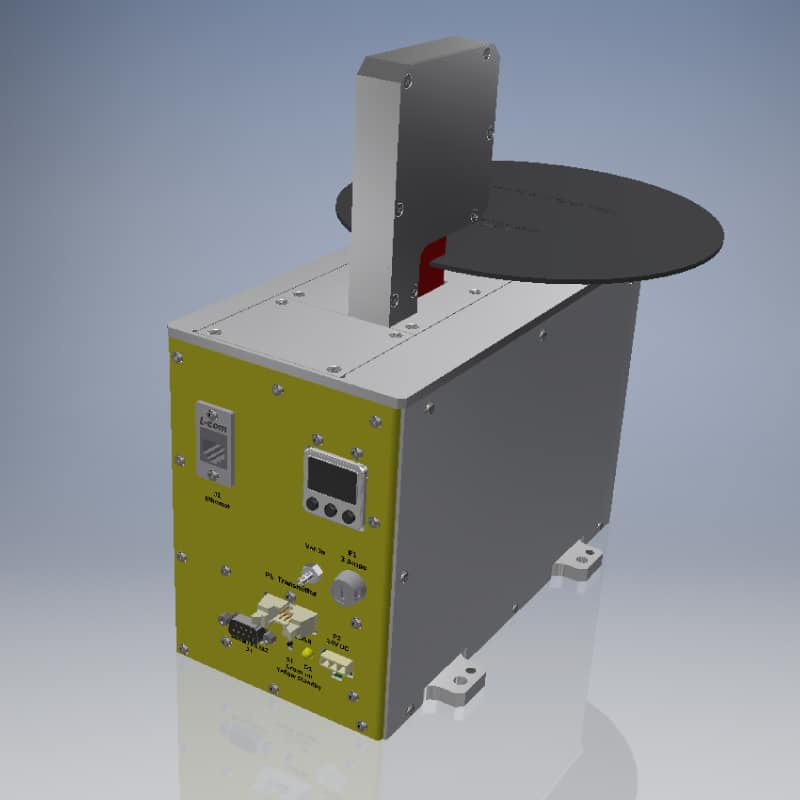

CLP – Vacuum Cassette to Cassette Load Port for 25 & 50 wafer cassette

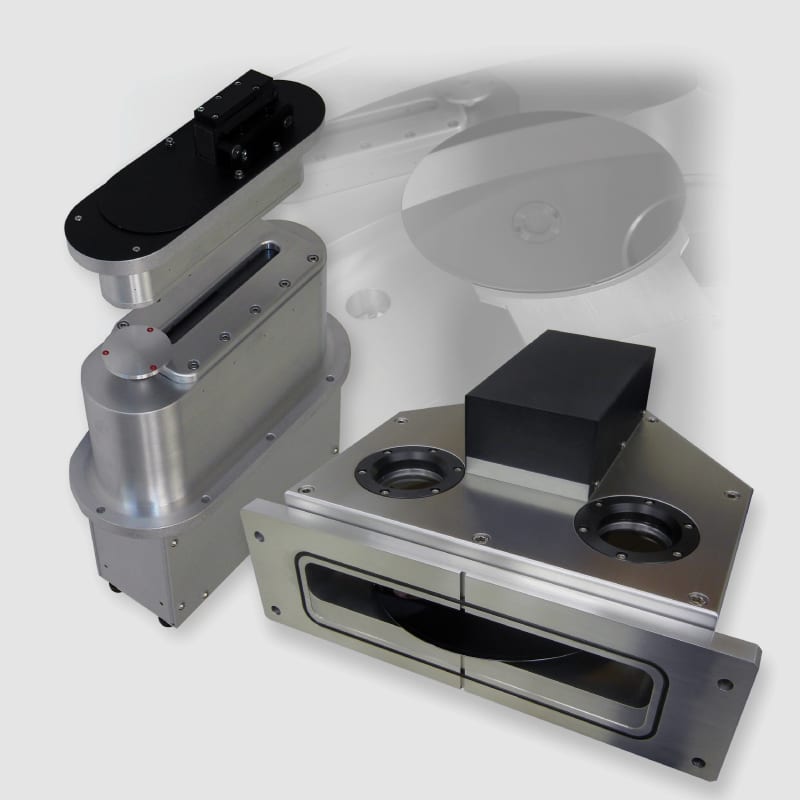

MLP – Vacuum Mini Load Port for Single wafer up to a 4-wafer cassette

MLP / CLP FEATURES

MLP-200 / MLP-300 OPTIONS

CLP-200/300 SPECIFIC FEATURES

CLP-200/300 OPTIONS

Vacuum and Atmospheric Cassette Load Ports

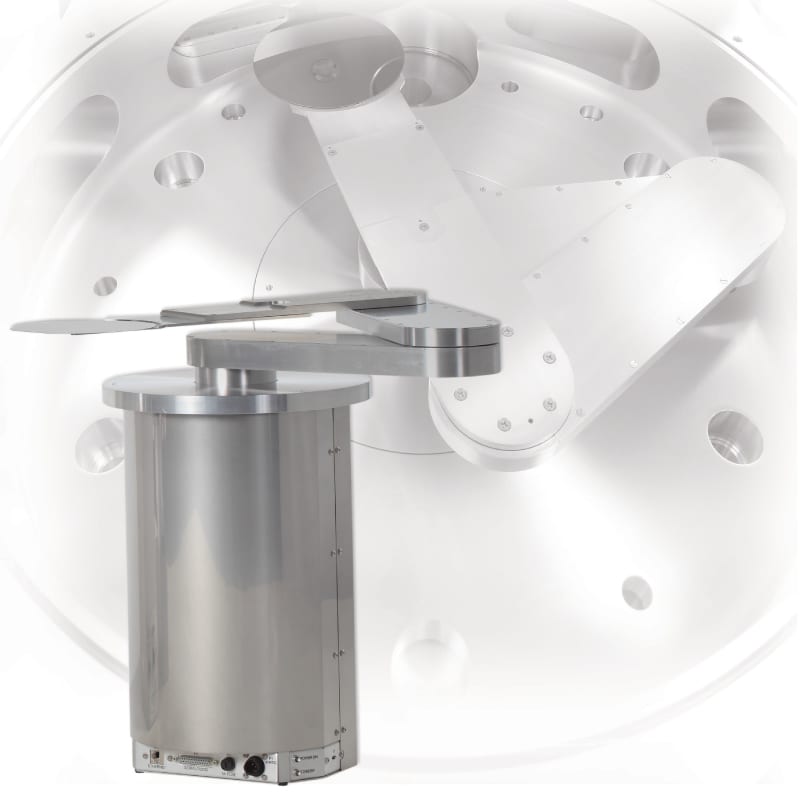

Designed to provide cassette loading and unloading capabilities for the Constellation family of cluster systems our Vacuum Cassette to Cassette Load Ports (CLP) can be customized to adapt to a customer’s specific requirements. The various Load Port configurations are built around the Hine Automation Vacuum Elevators with material indexing and positional sensing capabilities.

The Vacuum Mini Load Port (MLP) is designed as a single and multi-wafer Load Port to provide loading and unloading capabilities for Hine’s Integrated Wafer Handling Systems. The MLP configuration is cost-effective solution for application where a full Cassette is not required. The MLP also includes a self-centering design for the cassette and wafer, eliminating the need for a positional alignment device.

Full system integration requires only limited facilities connections and an Ethernet control interface. With a complete onboard control system, our Load Ports function as an intelligent material handling sub system.

PRODUCT SPECIFICATIONS

Specifications | Mini-Load Port (MLP) | Manual Door CLP | Autodoor CLP |

Wafer Sizes | ≤ 200mm 300mm (for MLP-300 only) | ≤200mm 300mm (for CLP-300 only) | |

Door Open/Close Time | N/A | 16 seconds | |

Air Pressure (Autodoor) | N/A | ||

Mapping Time | N/A | 20 seconds | |

Payload Capacity | Up to 34kg | ||

Base Operating Pressure | <5.00 E-6 Torr | ||

Leak Rate | <2.0 x 10-8 scc He/sec | ||

Total Weight | ~110Kgs (240 lbs.) | ||

Reliability | N/A | 3,000,000 MCBF | |