Case Study – Vertically Mounted LL, SL-300T

IT Administration

August 30, 2023

Continuing to Push What’s Possible!

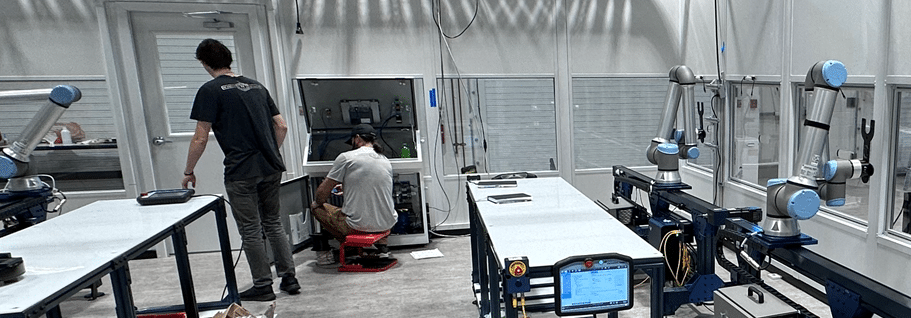

Vertical-Mounted Wafer Handling Load Locks

Hine Automation’s automated load lock designs eliminate the need to vent and evacuate the OEMs process chamber prior to each process cycle. These wafer-handling load locks offer various levels of functionality and integration and, until recently, have been exclusively horizontally mounted.

Hine Automation believes in creating leading-edge designs with the customer’s needs in mind. Experience drives design, and Hine Automation has always focused on implementing the right technologies to ensure it can offer the most innovative solutions to keep customers competitive.

An Expectation of Higher Performance

The expectation of higher performance and customization is what leads customers to Hine Automation. Hine’s reputation comes from a commitment to delivering quality solutions that require frequent evaluations of the company’s operations. As a result, Hine innovates by continuing to invest in the future of its customers, people, and processes. Additionally, it raises the bar for what is possible for state-of-the-art robotic components and automation systems.

By understanding the challenges that OEMs face, Hine’s experienced engineers create solutions to optimize performance and increase the customer’s overall efficiencies.

An Expectation of Higher Performance

Hine’s Vertically Mounted LL, SL-300T places the wafer inside the tool from the top, simplifying the loading process. However, because the motion is vertical rather than horizontal, more force, and additional customization was necessary. Hine adjusted by creating a brake to slow down the movement of the arm, allowing the wafer to safely and accurately be transferred into the process chamber.

Vertically Mounted LL, SL-300T Features:

- Unique vertical positioning

- Better accessibility

- Reduced System Footprint

- Wafer handling up to 300mm

- Safety Interlock

- Wafer Sensors

The Promise of Innovative Solutions

Semiconductor manufacturing consists of a large number of steps that can each require unique configurations. Standard solutions may be suitable for some installations, but a custom design that adapts to a customer’s process can significantly improve production. Improvements often create higher throughput, better quality, and lower costs. When it comes to innovation, Hine always looks to push what is possible and to build cutting-edge solutions.

Delivering performance, reliability, and service:

- Plug-and-play solutions

- Superior user experience

- Flexible and nimble

- Rooted in integrity and transparency

- Cost reduction

- Quality control

- Combined efficiency in speed and quality

About Hine Automation:

With more than 30 years of deep experience in the semiconductor space, Hine’s technology and design development are consistently relevant to the evolving market. Whether in the very early stages of a customer’s project or modifying an existing solution, Hine sets the precedence of uncompromised quality and versatility in design and manufacturing.

For more information on Hine Automation, visit https://hineautomation.com/.