The Future of Precision: Hine Automation HA-75C and HA-76 Vacuum Aligners

IT Administration

October 25, 2023

The HA-75C/76 vacuum aligners, built upon extensive research and customer feedback, are designed to meet the rigorous standards of today’s semiconductor production environments. These state-of-the-art aligners redefine how we perceive efficiency and accuracy in wafer alignment.

Transforming Wafer Handling with Enhanced Sensors

Many traditional vacuum aligners are designed with a significant limitation —restrictive wafer size visualization — often necessitating manual adjustments when changing wafer sizes. Hine’s HA-75C/76 models use larger sensors to eliminate this problem. The enhanced sensor capacity decreases downtime by allowing a broader range of wafer sizes to be processed without physical modification to the equipment or the need to break vacuum.

Increased sensor operation simplifies wafer handling processes, minimizes downtime, and reduces the potential for human error, thus creating a substantial operational advantage.

High-Temperature Wafer Compatibility

The inability to handle high-temperature wafers consistently limits many traditional aligners. The HA-75C and HA-76 have been methodically designed to manage wafers at elevated temperatures. This translates to fewer equipment transitions, increased throughput, and reduced risk of wafer damage due to temperature-induced factors. In addition, the system no longer needs to “cool down” the wafer before transferring it for alignment.

Benefits of the HA-75C and HA-76

- Efficiency: The vacuum aligners allow for rapid transitions between different wafer sizes and seamless handling of high-temperature wafers without the need for cooling stations or manual adjustments, significantly reducing operational times.

- Accuracy: The expanded visualization capability and temperature resilience ensure more precise alignment, which is vital in processes where even minor misalignments can lead to significant operational setbacks.

- Cost-effectiveness: The streamlined process, combined with the elimination of additional components or frequent adjustments, leads to long-term operational cost savings.

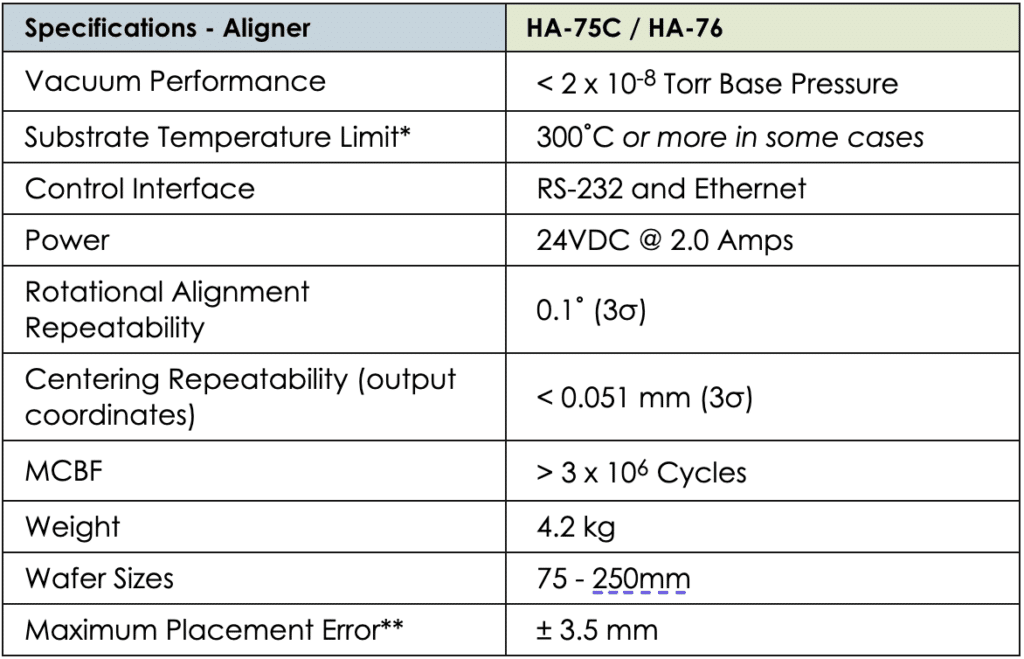

* Can support substrates at higher temperatures upon request, changes to standard aligner configurations may affect performance specifications.

** Wafer placement onto the aligner prior to aligning, larger wafer placement errors will result in reduced repeatability as specified.

With the industry’s increasing demand for tools that combine efficiency with precision, the HA-75C and HA-76 are timely additions to the robust Hine Automation product line. They represent the company’s commitment to innovation and a deep understanding of the sector’s technical requirements.

About Hine Automation:

With deep experience in the semiconductor space, Hine’s technology and design development are consistently relevant to the evolving market. Whether in the very early stages of a customer’s project or modifying an existing solution, Hine sets the precedence of uncompromised quality and versatility in design and manufacturing.

For more information on Hine Automation, visit https://hineautomation.com/.